The West Virginia AP1000 project represents a cornerstone investment in American energy independence. This advanced pressurized water reactor will deliver 1,117 megawatts of clean, reliable baseload power to support regional economic growth for 60+ years.

Project Summary

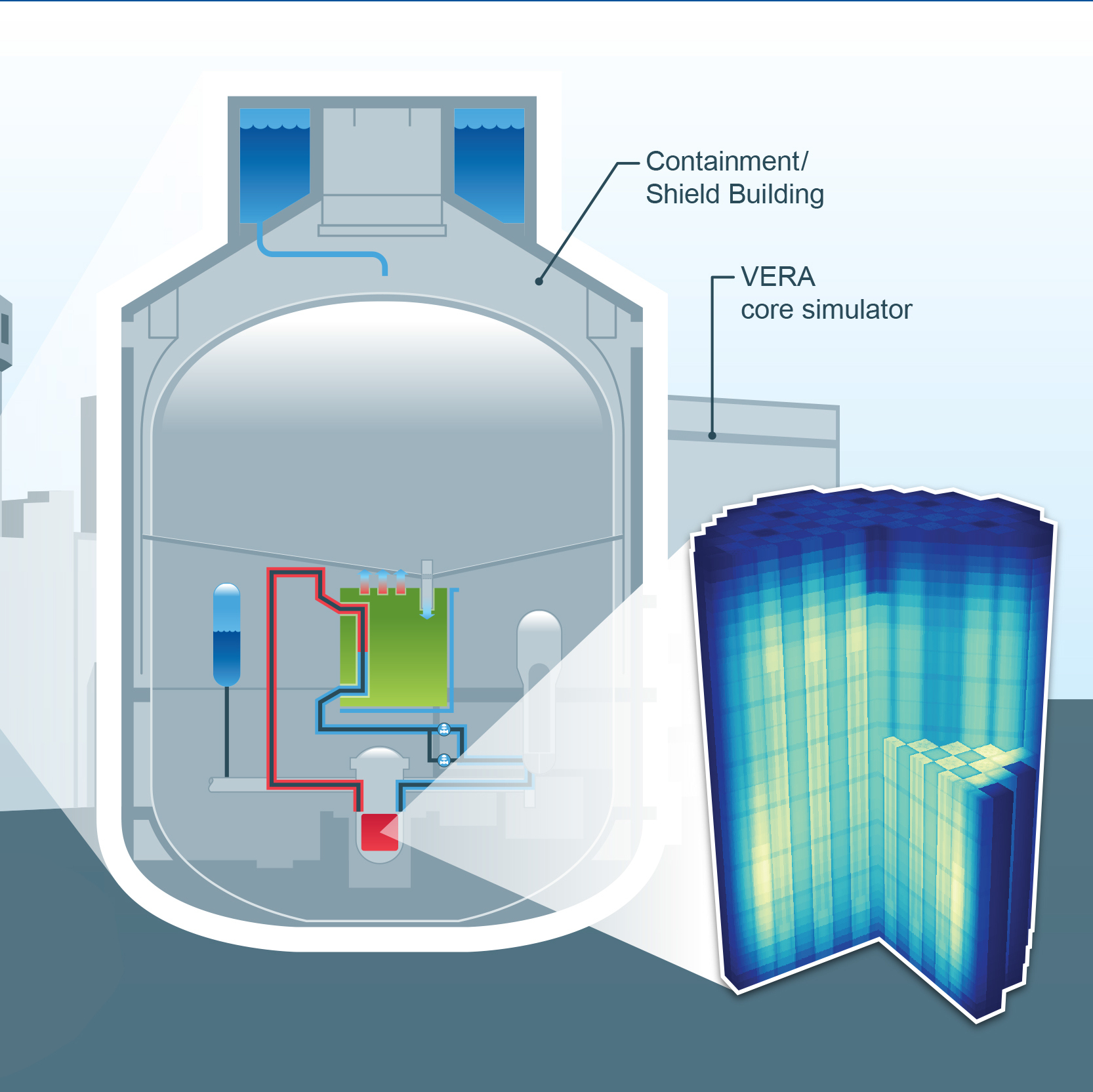

Passive Safety Systems

The AP1000 features revolutionary passive safety systems that rely on natural forces—gravity, natural circulation, and compressed gas—rather than active mechanical components or operator intervention. In the unlikely event of an incident, these systems automatically activate and function for at least 72 hours without power, water, or human action.

Simplified Design

With 50% fewer valves, 35% fewer pumps, and 80% less piping than conventional reactors, the AP1000 reduces complexity while enhancing reliability. Fewer components mean fewer potential failure points and simplified maintenance.

Advanced Containment

The steel-and-concrete containment structure features a double-shell design with an outer shield building that protects against external events. The modular construction approach ensures consistent quality and reduced construction timelines.

Digital Control Systems

State-of-the-art digital instrumentation and control systems provide operators with comprehensive real-time monitoring and automated safety responses, representing a significant advancement over analog systems in older reactor designs.

Seismic & Extreme Weather Protection

Engineered to withstand significant seismic events, extreme temperatures, flooding, and hurricane-force winds. The robust design ensures continuous operation or safe shutdown during natural disasters.

Impressive Output Specs